9. Start date and End date

Start date shows the date of initial application

of the part and "blank" means the part has been applied

from the time of initial production. End date shows the date of

end time of part's application and "blank" means the part

is still applying.

10. Model and related serial number

MODEL |

SERIAL No. of ENGINE |

SERIAL No.of FRAME |

REMARK |

VJ150 |

VJ150E1000001~ |

KMYBA4BLB5C000001~ |

EURO 2 |

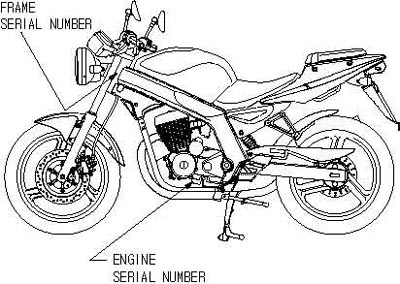

11. Illustration

The part illustration in the part list is only used

help explanation and may have minor difference with the actual

appearance of the part.

12. Location of stamped serial number